Noise protection

The Sonation SSH series

Learn how Sonation products can improve your lab environment and how they are manufactured.

With the different models, almost any device can be insulated. If a device does not fit into one of the series products, special designs with customer-specific dimensions are also possible.

General information

The temperature and operating data monitoring module APPS (Active Pump Protection System) enables you to perfectly protect your sensitive and important equipment. All important operating data such as temperature, current consumption and the function of the fans are constantly monitored. In case of an error, an optical and acoustic warning is given.

Try before buy

We will gladly supply you with a demonstration unit to try out. If you are not satisfied with the sound protection hood, you can return it without any further obligations.

Insulation

The insulation material used is oil and water repellent as well as flame retardant according to FMVSS 302 and DIN 75 200.

Ventilation and cooling

Fans trimmed for noise minimization are used to dissipate the pump waste heat. The air ducting inside the box is designed to provide optimum cooling for the pump, yet prevent sound from entering through the air inlet and outlet openings.

Sound insulation

The sound reduction is up to 16dB(A) which corresponds to a reduction of about 80% of the perceived loudness.

Accessibility

To gain access to the pump, e.g. to read the oil level, the front can be removed and reattached with a flick of the wrist using quick-release fasteners.

Flexibility

The sound protection hoods are equipped with pump-specific cover plates. These cover plates allow the sound protection hood to be adapted to the respective pump type. If a different pump is to be insulated, only the cover plate needs to be replaced. Thanks to magnetic locking, the cover plates can be removed quickly without tools.

Flange kits

With some sound protection hoods, it makes sense to extend the pump connections for vacuum and/or exhaust connections. This allows attachments such as oil mist filters or similar to be connected outside the sound protection hood. For this purpose, we offer flange kits in various sizes and lengths.

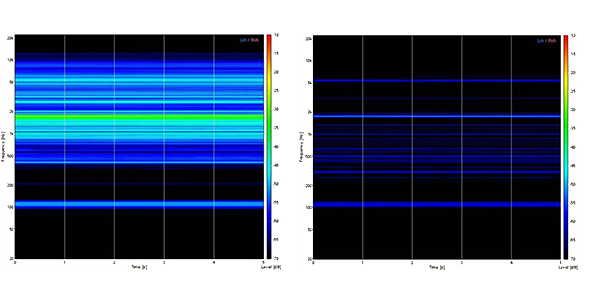

Comparison of noise levels

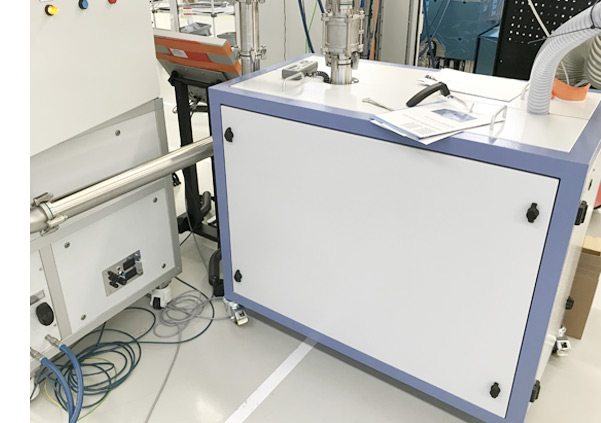

Solutions for special applications

Sound enclosure suitable for the Fritsch Pulverisette P7 Planetary Micro Mill

SSH-SE-PS2

Technical data:

Dimensions [mm]:

Outside: 620x450x800mm (WxHxD)

Interior: 502x405x685mm (WxHxD)

Weight [kg]: 32

Insulation [dB(A)]: 20

Insulation material: 40mm PUR foam.

Surface: Oil and water repellent.

Ventilation: Speed-controlled fans with overtemperature monitoring.

Power supply: 100-240V AC (50/60Hz)

Sound enclosure suitable for Edwards iXH610 vacuum pump

SSH-SE-PS2

Technical data:

Dimensions [mm]:

Outside: 650x1040x1200mm (WxHxD)

Interior: 550x830x1100mm (WxHxD) (height from collection tray)

Insulation material: 40mm PUR foam.

Surface: Oil and water repellent.

Expected noise reduction: About 75%.

Flammability:

- Meets FMVSS 302 or DIN 75200.

- ISO 3795, burning rate < 100mm/min.

- Powder coated steel tube frame, 50mm.

- Inset removable soundproof panels, on all sides, top and bottom.

- Front and back designed as doors.

- Two-piece removable top cover.

- Side panels removable by quick release fasteners.

- Heavy duty casters with brakes.

- Integrated stainless steel drip tray.

- Vibration decoupling via four dampers.

- Intake air via front air inlets, exhaust air via 100 mm flange in cover.

- Feed-throughs for control panel cable, vacuum flange, exhaust flange, nitrogen line, power cable and hoses for cooling water.

- Temperature monitoring with overtemperature alarm.

- Integrated liquid / oil leakage sensor with alarm.

Sound enclosure for an OLV Screwline SP630F pump

SSH-SE-SL01

Technical data:

Dimensions [mm]:

Outside: 800x1300x2120mm (WxHxD).

Inside: 700x1250x2020mm (WxHxD)

Insulation material: 40mm PUR foam, fleece laminated.

Surface: oil and water repellent.

Fire behavior:

- Meets FMVSS 302, DIN 75 200.

- ISO 3795, burning speed < 100mm/min