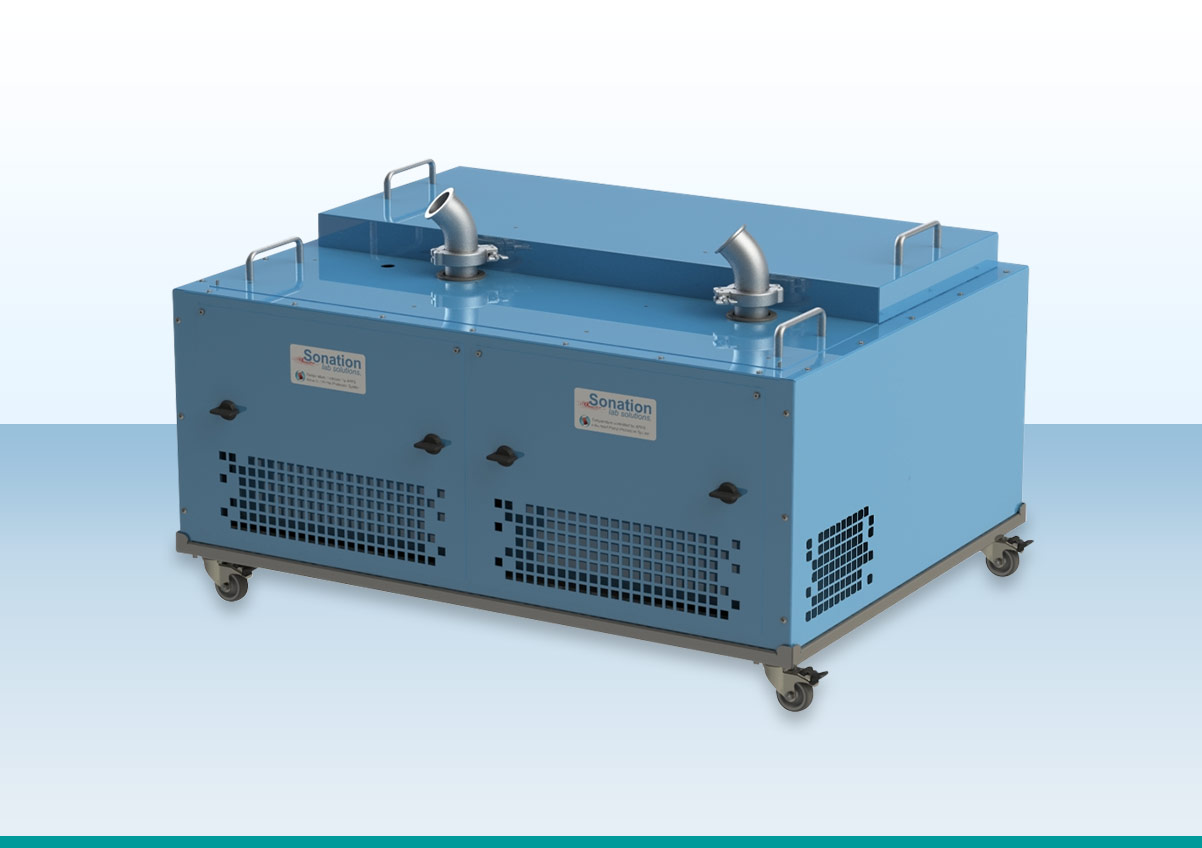

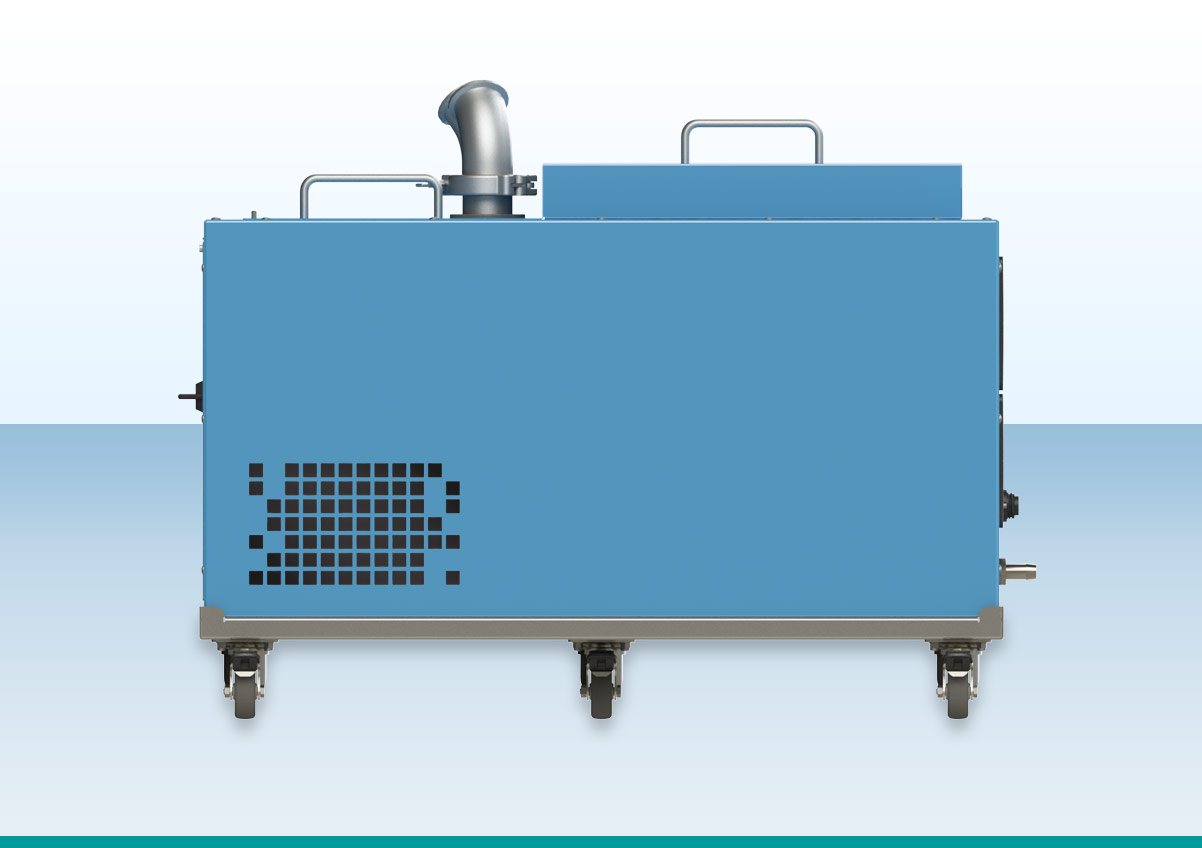

Model SSH-ECL

This sound protection hood insulates both backing pumps of the Thermo Scientific Orbitrap Fusion Eclipse. It is installed under the instrument table and thus requires no additional space. The included oil tray on wheels makes it easy to move the pumps for service.

Configuration

Benefits

Sound protection

The noise level in the laboratory is significantly reduced which prevents hearing damage and leads to higher concentration and productivity.

The noise level in the laboratory is significantly reduced which prevents hearing damage and leads to higher concentration and productivity.

Universal and flexible

By using pump-specific interchangeable covers, the sound protection hood fits perfectly to the pump used. If a different pump is to be insulated at a later date, this is easily possible by replacing the cover.

By using pump-specific interchangeable covers, the sound protection hood fits perfectly to the pump used. If a different pump is to be insulated at a later date, this is easily possible by replacing the cover.

Simple commissioning

Commissioning of the sound protection hood can be carried out by the end user within a few minutes.

Commissioning of the sound protection hood can be carried out by the end user within a few minutes.

Easy pump access

Both the cover and the front can be removed with a flick of the wrist via quick-release fasteners. This makes it easy to check the oil level, operate the gas ballast valve or perform other work on the pump at any time.

Both the cover and the front can be removed with a flick of the wrist via quick-release fasteners. This makes it easy to check the oil level, operate the gas ballast valve or perform other work on the pump at any time.

Internal pump socket

All sound protection hoods are equipped with an internal socket for connecting the vacuum pump. This means that only one socket or cable is required to supply power to the pump and the sound protection hood. Separate power supply of the pump and the sound protection hood is also possible.

All sound protection hoods are equipped with an internal socket for connecting the vacuum pump. This means that only one socket or cable is required to supply power to the pump and the sound protection hood. Separate power supply of the pump and the sound protection hood is also possible.

Temperature monitoring with alarm function

The exhaust air temperature is continuously monitored. In the event of overheating, a visual and acoustic alarm is triggered.

The exhaust air temperature is continuously monitored. In the event of overheating, a visual and acoustic alarm is triggered.

Temperature-controlled fans

The speed of the fans is controlled depending on the required cooling capacity, which contributes to an increased service life as well as optimal noise minimization.

The speed of the fans is controlled depending on the required cooling capacity, which contributes to an increased service life as well as optimal noise minimization.

Wide range input

The sound protection hood can be operated on 110V networks as well as on 230V networks.

The sound protection hood can be operated on 110V networks as well as on 230V networks.

Emergency shutdown function

When a critical internal temperature is reached, it is possible to automatically switch off the internal socket to prevent a defect.

When a critical internal temperature is reached, it is possible to automatically switch off the internal socket to prevent a defect.

Technical data

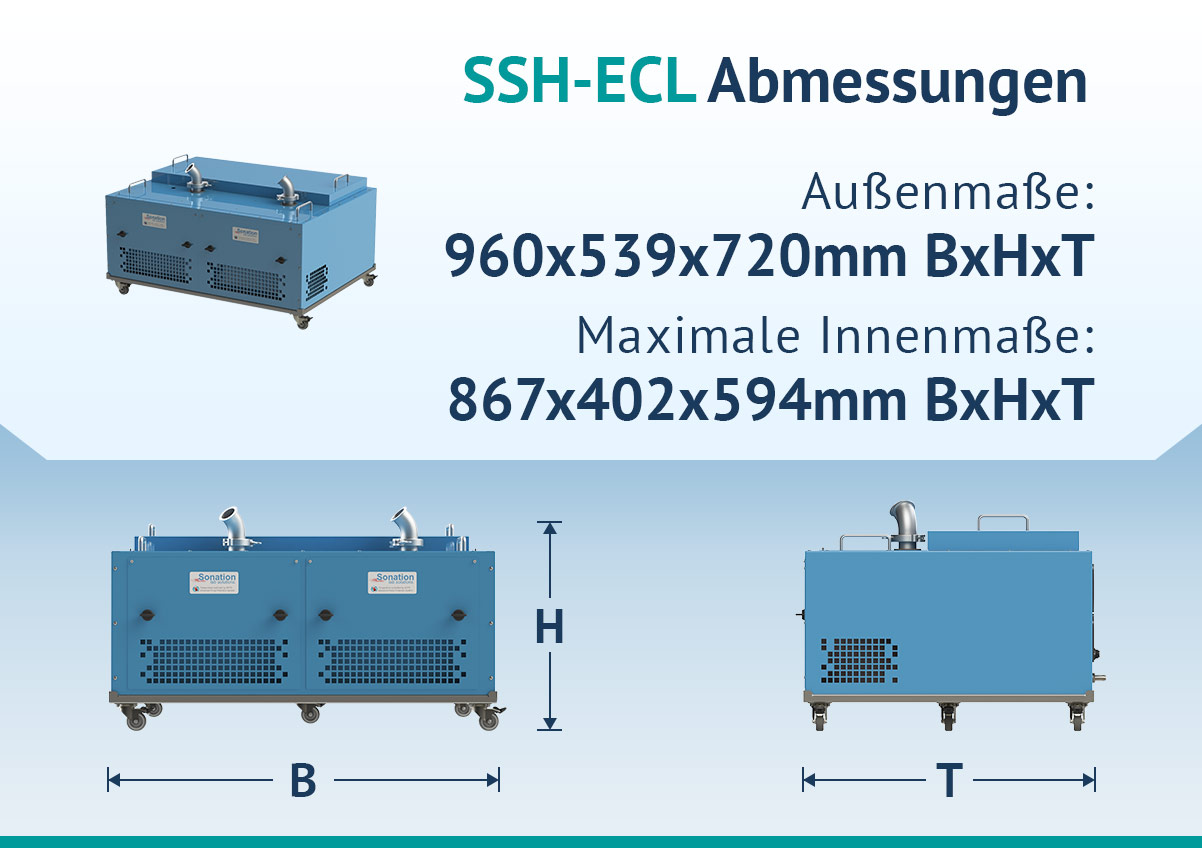

External dimensions

960 x 539 x 720mm (WxHxD)

Maximum internal dimensions

867 x 402 x 594mm (WxHxD)

Noise reduction

About 16dB(A) -> Corresponds to about 80% noise reduction

Insulation material

High-quality insulation made of environmentally friendly recycled material.

PUR-based acoustic foam with fleece-laminated, oil- and water-repellent surface.

Flammability: Complies with FMVSS 302 and DIN 75200 respectively.

Accessories

Compatible accessories for this product:

The display can be connected to all Sonation products with APPS module. The display shows at a glance all important data such as temperature, current drawn by the vacuum pump and the function of the fans.

Add to requestProduct details

Stainless steel oil tray on wheels for use with the SSH series. Eases the pump service and helps to keep the floor clean.

Add to requestProduct details

Oil leakage in vacuum pumps can quickly lead to damage or even total failure of the pump. The oil leak sensor in conjunction with an APPS module constantly monitors whether oil is collecting in the oil tray. If a leak is detected, an alarm is signaled visually and acoustically.

Add to requestProduct details

With the Sonation oil change kit, the oil drain plug of the pump is replaced by a convenient drain adapter with ball valve. The complete oil can then be easily drained in one easy step.

Especially with pumps that stand directly on the floor, the pump often had to be lifted for the oil change until now. With the flat oil drain sump, this is no longer necessary. This makes every oil change a clean and simple job.

Especially with pumps that stand directly on the floor, the pump often had to be lifted for the oil change until now. With the flat oil drain sump, this is no longer necessary. This makes every oil change a clean and simple job.

Add to requestProduct details